Questions? We've got answers.

Save money, increase productivity and improve quality. Whether you use single cylinders or have gases piped, the Gastrak® service can help.

Air Products offers thousands of products and services to a variety of different industries. This scope and experience has enabled us to develop a deeper understanding of the demands of these industries, and of your particular needs.

We have provided information most relevant to you within this industry section, but you may find information in other related industries of interest as well. The attached list is provided as a convenience for you or you can click on “Industries” in the top navigation for a full listing.

Compressed argon gas and liquid argon in a variety of purities and in various modes of supply around the world thanks to our network of storage and transfill facilities.

In addition to its use as a respiratory gas for healthcare applications, its strong oxidizing properties benefit many industries by improving yields, optimizing performance, lowering costs and reducing carbon footprint compared to other fuels.

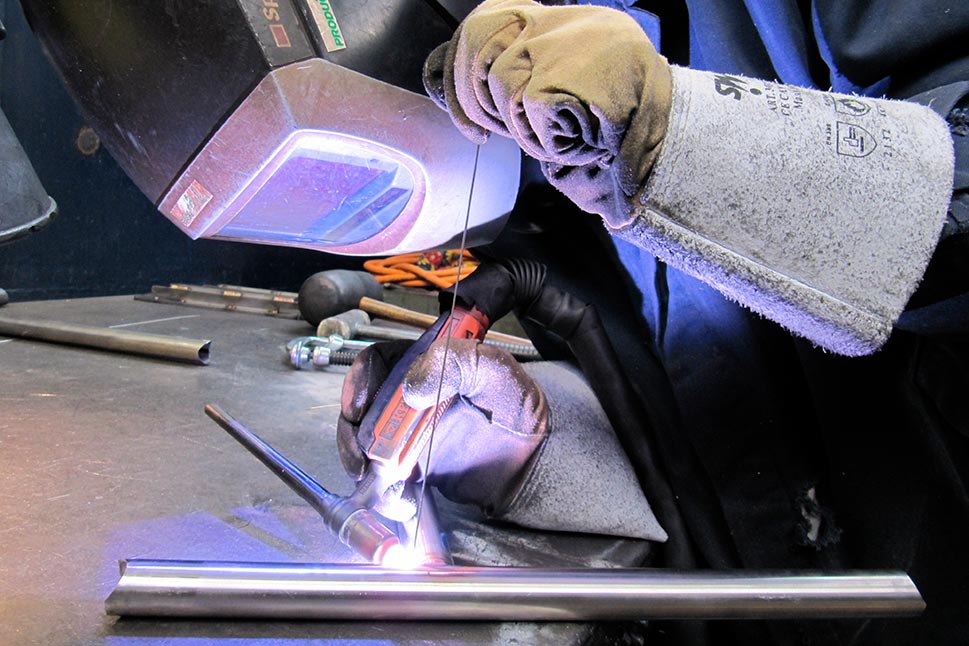

Acetylene is the primary fuel for oxy-fuel welding and is the fuel of choice for repair work and general cutting and welding, Acetylene produces the hottest and most concentrated primary flame of all industrial fuel gases.

A range of gases, technologies and services for metal fabrication, whether you are welding, cutting, thermal spraying, brazing or gouging.